Electric Contact Pressure Gauge

Electric Contact Pressure Gauge is widely used in automatic controlling of devices and electromechanical equipments in many industries such as petroleum, chemical industry, power station, and metallurgy.

Specifications

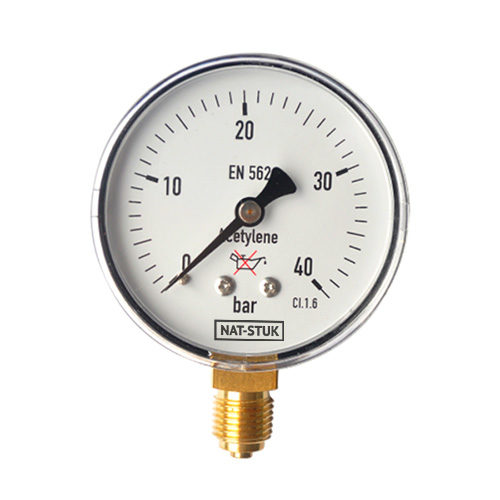

Dial size: 4″ (100 mm)

Case: 304 Stainless Steel case.

Wetted parts: 316 Stainless Steel

Lens: Polycarbonate

Pressure Range: Vac to 15,000 psi/Bar

Description

Electric Contact Pressure Gauge is widely used in automatic controlling of devices and electromechanical equipments in many industries such as petroleum, chemical industry, power station, and metallurgy.

Specifications

Size: 4″ (100 mm)

Accuracy: 1.0% of full scale (ASME B40.100 Grade 1A)

Case and ring: 304 Stainless Steel matte finished

Lens: Polycarbonate dome

Wetted parts: 316 Stainless Steel

Operating Temperature: Ambient: -20 to 60°C (-4°F to 140°F)

Process fluid: max 60°C (140°F)

Dial: Aluminum with black & red markings

Pointer: Black aluminum

Connection: 1/4″ or 1/2″ NPT or BSP bottom

Ranges: Vacuum to 15,000 psi/Bar

Protection degree: IP65

Switch: 1 NO contact

Protection

– If pressure gauges are to be used for steam service, a siphon tube filled with water must be installed between gauge and line to prevent live steam from entering the Bourdon tube.

– A gauge cock should be installed in the pressure line. This might be the standard shut-off valve or a needle valve for throttling pressure pulses.

– If severe pulsation exists, the gauge should be protected by adding a throttling orifice

screw in the gauge socket or by addition of a pulsation damper, such as a snubber.

– A diaphragm seal should be used in applications where process media should not come in contact with gauge.

We invite you to check out our post: When should you use liquid-filled pressure gauges?